The three main types of hydraulic motors are gear motors, vane motors, and piston motors. Each type has its strengths, but piston and vane motors are the most widely used in applications requiring high efficiency, precise control, and high torque at low speeds.

This article specifically compares vane vs piston hydraulic motors. We'll go into depth to explain their operation, advantages, and best-use cases in hydraulic systems.

There are three main types of hydraulic motors, each suited for different applications:

The focus here is on vane and piston motors, as they are commonly used in hydraulic systems that demand high pressure and precision control.

A hydraulic vane motor operates using vanes inside a rotor that slide in and out due to hydraulic pressure. The hydraulic fluid enters the motor and pushes against the vanes, causing the rotor to rotate. This rotation transfers power to the output shaft, driving machinery.

While vane motors tend to be lightweight and cost-effective, they cannot handle high pressures like piston motors.

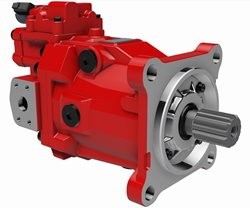

A piston motor operates by using multiple pistons inside a cylinder block. Rotary motion is caused when the pistons move, this produces high torque at low speeds. Piston motors typically fall into two categories:

|

Feature |

Vane Motor |

Piston Motor |

|

Efficiency |

Moderate |

Highly efficient |

|

Torque Output |

Moderate torque |

Generate high torque at low speeds |

|

Operating Pressure |

Medium pressure |

High pressure |

|

Durability |

Good, but lower lifespan than piston motors |

Very durable, long lifespan |

|

Best for Applications That Require |

Smooth, steady speed at moderate pressure |

High power, high efficiency, and precise control |

|

Cost |

Lower cost |

Higher cost but more efficient |

When selecting a hydraulic motor, it is essential to consider efficiency, pressure requirements, torque output, and application type.

Hydraulic motors offer powerful and efficient performance, but choosing the right type depends on application-specific needs. Whether you need high torque, high efficiency, or smooth operation, both vane and piston motors have their place in industrial and mobile applications.

Posted by admin in category Hydraulic Motors Advice on Tuesday, 14th October 2025

Call our knowledgeable team Mon–Fri 8:30am–5pm

Systems & Components Division 01427 874445

sales@hydrastore.co.uk

Hose Division 0121 326 6395

hoses@hydrastore.co.uk

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy