When did someone last check the fluid level in your hydraulic power pack? Are the filters still clean or badly clogged? If you’re not certain then you're not alone.

Hydraulic systems don’t always fail fast - they fail quietly. And when they go, the downtime, cost of repair, and safety hazards can bring your operation to a standstill. That’s why hydraulic power pack maintenance isn’t optional - it’s the difference between reliable uptime and a costly breakdown waiting to happen.

Here’s how to build a realistic maintenance routine that fits your setup, protects your equipment, and keeps everything running smoothly and efficiently.

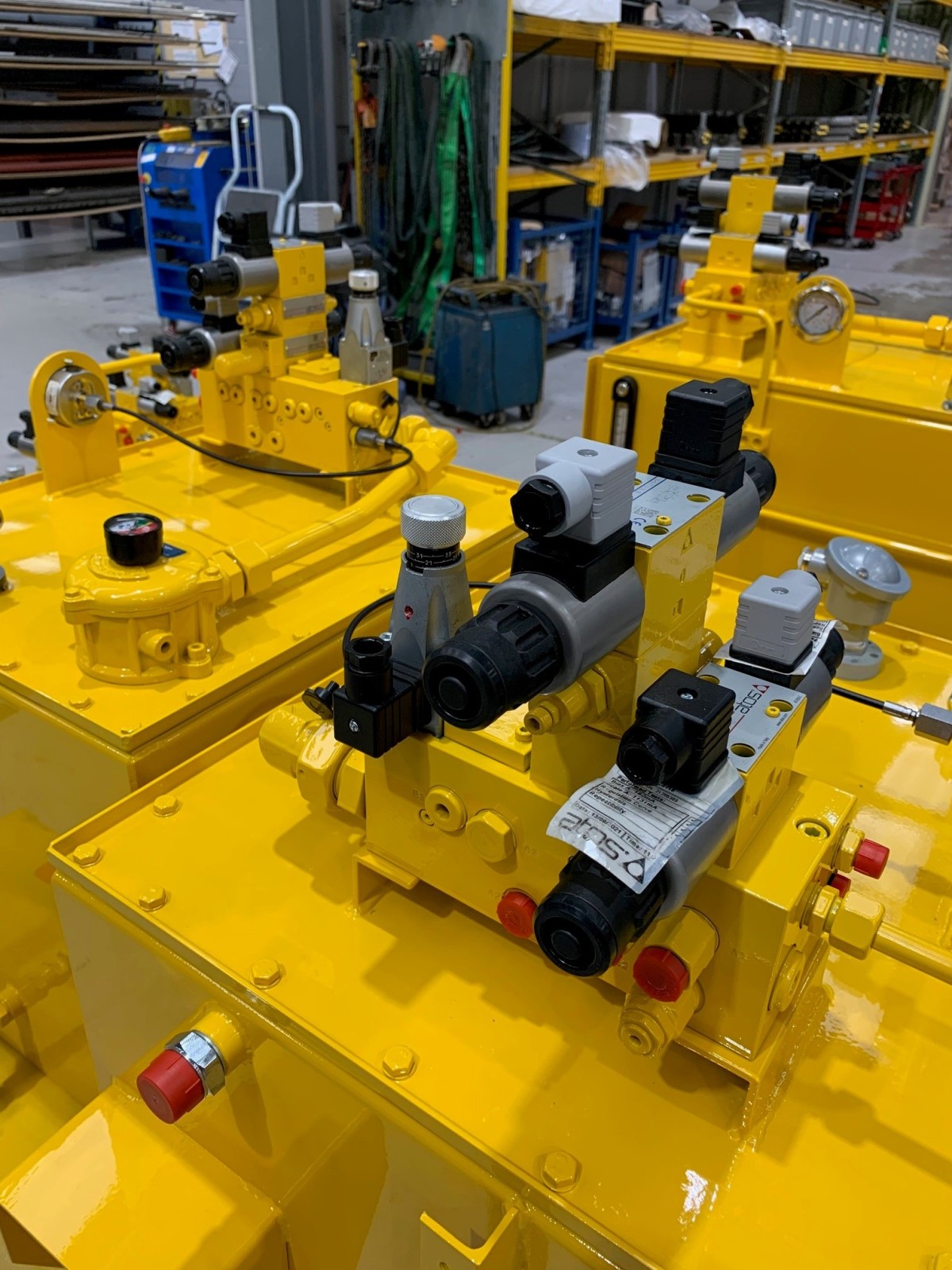

Every hydraulic system depends on the power pack to operate efficiently. Whether it’s running presses, lifts, or industrial machinery, the power pack delivers hydraulic pressure, flow, and control - and if it’s not maintained, the entire system suffers.

Proper hydraulic maintenance:

Let’s get straight into it. Here's a maintenance checklist your team can use weekly, monthly, and annually.

Simple, practical, and often overlooked:

Watch for these early warnings:

These issues are all signs that the system is either already compromised or on the brink. Don’t wait.

Preventive maintenance helps maintain system efficiency, extends service life, and reduces the need for emergency call-outs. Done right, it lowers the total cost of ownership and gives you predictable uptime - which is critical in any industrial or mobile application.

For example, a simple fluid change and filter replacement could prevent hydraulic system failures that cost thousands in downtime.

Your hydraulic power pack is one of the most important working components of a hydraulic setup. If you perform maintenance regularly and follow a maintenance schedule, your system will reward you with reliability, efficiency, and a longer life.

Skip it? Well - don’t be surprised when a seal bursts, fluid overheats, or the whole thing grinds to a halt.

Hydrastore offers expert advice, parts, and support to keep your hydraulic system running like it should. Whether you’re setting up a new maintenance routine or responding to a fault, we’re here to help.

Posted by admin in category Hydraulic Power Packs Advice on Tuesday, 16th December 2025

Call our knowledgeable team Mon–Fri 8:30am–5pm

Systems & Components Division 01427 874445

sales@hydrastore.co.uk

Hose Division 0121 326 6395

hoses@hydrastore.co.uk

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy