When you're putting together a hydraulic power pack (HPU) spec, it's easy to get tunnel vision, chasing flow rate, pressure or price. But miss a few key checks, and you can end up with a unit that underperforms, overheats, leaks, or fails early. Most of the time, the mistakes are simple and avoidable. It's just about knowing where the usual problems start.

Here are 9 of the most common HPU specification mistakes we see at Hydrastore, and what to do instead.

Mistake: Sizing the reservoir too small for the system's flow rate.

A small reservoir might seem like a space-saving win, but if it doesn't allow the oil time to cool and de-aerate, you’re setting yourself up for foaming, overheating, or cavitation.

What to do instead:

Tip: Always allow space for thermal expansion and top-up volume.

Mistake: Choosing poor or undersized filters, or skipping them altogether.

Dirty oil is the number one cause of early system failure. Contamination leads to premature wear on pumps, valves, and actuators.

What to do instead:

View our stock of hydraulic filters and contamination control products

Mistake: Using general-purpose oil instead of fluid specified for the operating environment.

Hydraulic fluid needs to maintain the right viscosity at all operating temperatures. Too thin, and you'll get metal-to-metal contact. Too thick, and the pump cavitates.

What to do instead:

Mistake: Matching pump displacement but forgetting startup loads, backpressure or duty cycle.

Motors running over capacity will run hot and fail fast.

What to do instead:

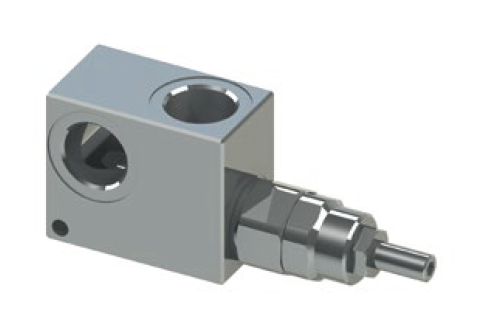

Mistake: No pressure relief valve or a badly specified one.

If there's no proper way to relieve excess pressure, the system becomes a safety risk.

What to do instead:

Mistake: Using mismatched hoses and fittings, or skipping pressure rating checks.

This one causes leaks, bursts, and excessive pressure loss.

What to do instead:

See our comprehensive range of hoses and fittings with info on pressure and compatibility tables.

Mistake: Assuming the oil will stay cool without any active cooling or thermal checks.

Hydraulic oil starts breaking down over 65°C. If you’re not dissipating heat, you’re cooking seals and reducing fluid life.

What to do instead:

Mistake: Running without sight gauges, temperature sensors or alarms.

These are small components that prevent big problems.

What to do instead:

Mistake: Designing a system that’s a nightmare to inspect, drain or service.

This leads to skipped inspections and long-term neglect, which costs more than the job saved.

What to do instead:

Most of the common hydraulic power pack mistakes come down to rushing the spec, or using a copy/paste approach from a different system. Each HPU needs to match its environment, duty cycle and system performance needs.

Getting it right the first time keeps your hydraulic equipment running smoothly, your maintenance predictable, and your system lifespan long.

If in doubt, talk to our expert team. Hydrastore can help spec, build, and support high-quality HPUs for industrial applications across the UK.

Q: What’s the most common cause of hydraulic system failure?

A: Contaminated fluid. Most wear and tear in hydraulic pumps, valves and actuators comes from dirt or degraded oil.

Q: How often should I change hydraulic filters?

A: Depends on hours and environment, but many systems need filter checks every 500-1000 hours. Use pressure gauges to monitor drop.

Q: How do I know if my reservoir is too small?

A: Look for signs like overheating, foaming fluid, or cavitation at the pump inlet. A tank that’s too small won’t cool or de-aerate oil properly.

Q: Can I just use standard mineral oil?

A: Only if it meets the viscosity and spec range for your system. Wrong fluid can cause cold-start failures or overheating.

Q: What’s the right way to check fluid cleanliness?

A: Regular fluid analysis and monitoring ISO cleanliness levels. Use good filters and replace them before clogging.

Posted by admin in category Hydraulic Power Packs Advice on Wednesday, 28th January 2026

Call our knowledgeable team Mon–Fri 8:30am–5pm

Systems & Components Division 01427 874445

sales@hydrastore.co.uk

Hose Division 0121 326 6395

hoses@hydrastore.co.uk

Hydrastore use cookies to make the site run smoothly, enhance the content and to gather information on how you use it in order to improve and personalise your experience. See our Privacy Policy